The paper used for the production of these custom paper bags is of high quality. Considering the attractive look of the bags, it is impressive that they have been built to last long. Heavy-duty paper is one of the top-selling features of the custom paper bags wholesale category.

It can be used for different things, such as carrying dry goods in different forms. The heavy-duty paper also guarantees that the bag can be easily moved from one place to another without worrying about tearing. Also, the heavy-duty paper material conforms to the shape of the bag’s content, so it can be used to carry almost everything.

Custom paper bags wholesale with sturdy handles

The handles on this bag have been made to look presentable, but the looks do not define its strength. The cotton woven handles are sturdy. The bag’s handle is one of the defining features that influence its usage.

Many people would use the bag multiple times when the handle is strong enough to survive the strain. The manufacturers know this, and it is the reason why they have ensured only the strongest woven cotton or polymer handles have been fixed on these custom paper bags.

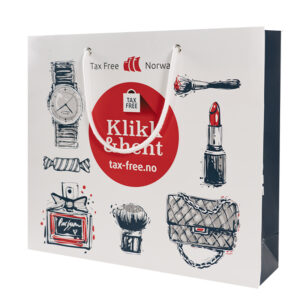

Stylish design

The customer paper bags have a unique look. It is not for carrying messy products only. The bags can be used stylishly. This is why it is a favorite used by many retailers and wholesale vendors to offer their clients different products. The stylish-looking custom paper bags blend with different fashion ensembles.

The slim look that remains unchanged when the content is not too bulky matches elegance if the user wants to portray it. The sturdy bags also guarantee no accidents such as ripped bags or handles while it is in use.

Customizable paper bags

The sturdy paper used to make these bags allow bulk buyers and business owners to customize the bags. The custom features include printing logos or brand messages on the bags.The high-quality paper bag surface provides the perfect medium to highlight brand logos or messages for maximum visibility.

This means any printed content on the paper bags can be seen by people nearby or far away. The bags can be printed with holiday colors during popular holidays at the end of the year or mid-year.

Printed materials that feature different colors are also suitable for these custom paper bags. And the color of the paper bag handle can be customized to meet the buyer’s expectations.

Bulk orders available for different sizes

The custom paper bags are available in different sizes. This is convenient for retailers who sell different types of products. It is also a good feature that prevents wastage. Smaller bags are available for businesses that sell products such as jewelry. At the same time, fashion houses and other companies can find larger sizes for their products.

The size preferences should be specified while placing bulk orders. The lead time for these bags is from ten days, depending on the bulk order.